Product recalls usually bring with them a sense of sudden death for various departments of the global economy. It is even more detrimental for sectors such as agriculture and food. While most consider it to be the “kiss of death”, the automotive industry lead by the leading manufacturers generally recall millions of vehicles globally and barely feel the damages.

In the case of the electronics industry, they fall in the middle of both food and vehicles. However, there are strongly impacted by performance defects and tons of other reasons that render as being serious. When these situations occur, they easily leave the global population at large returning stocks and market shares decreasing.

With that said, it should be noted that even though there are recalls within the electronics field, most people don’t actively notice them. So if you’re intending to avoid all of the problems that can occur with your products, read on as we dive into the top 10 tips for avoiding product recalls.

Design Integrity

When your products are still in the design stage, it’s best to ensure that they are 100% perfect. Even though perfection may seem a tad bit impossible, it’s highly recommended that all new products be designed with as little fault as possible. Fine-tuning any product takes a ton of time but it actively prevents the repeated redesign process and eliminates any and all the problems that can easily be embedded into the product.

Don’t Skimp On The Test Phase

When new designs are not properly tested, they can run into severe problems later on. Hence, prototypes must undergo stringent failure analysis multiple times. This provides the perfect testing ground to ensure that all problems are solved before the product can move on. In the rare case where faults go undetected, they become harder to rectify as the project progresses.

Design For Manufacturing

This is one of the most important stages within the design and production process. However, most companies think lightly of it and lump it into the testing phase. For better words, product development is only effective when the traditional steps are bypassed in an effort to implement the product and its design as part of a larger solution.

Designers are now running with the idea that products must fulfill the needs of each customer and specific requirements are designed into the product. In essence, both physical and virtual factories must be effective and capable of creating the product to meet the most accurate design specs.

The Supply Chain Should Be Thoroughly Checked

As pristine and precise as designs can be, they can easily fall short and fail miserably at the supply chain level. However, this only occurs when success and support are not provided. Hence, manufacturers must have the complete support that is needed from contractors, suppliers, sales outreach, and software developers. In some instances, the sales department also does its own set of checks to ensure that the product is properly optimized and ready.

Enquire About The Record And History Of The Supplier

Supply chains are rated based on how well its components perform. Within the electronics industry, this is the leading and most efficient form of product management. While OEMs tend to contain parts from numerous supply chains, each layer undergoes scrutinization to determine the accuracy of each component.

Since others will also be looking for reputable suppliers, they should look out for the Approved Vendors’ Lost that is shared with leading providers. The list usually complies with the highest standards and is continuously updated.

Keep Up With Regulations And Rules

Due to new environmental regulations coming onstream recently, several manufacturing industries are now being closely monitored. Over the last couple of decades, manufacturers are now being asked to follow the guidelines and regulations of WEEE, RoHs, and REACH. If ever manufacturers should fail to abide, then they run the risk of having their products pulled from every shelf around the globe.

Closer Collaboration Is Needed Between Suppliers, Distributors, OEM, And EMS Providers

Since the entire supply chain needs to work in perfect harmony, their delicate and meaningful relationship must carry out OEMs main task. Usually, equipment vendors are responsible for calling all teams involved in one space where they can all work towards the same goal. Over the last couple of years, distributors have also even done everyone involved a favor and brought the team together.

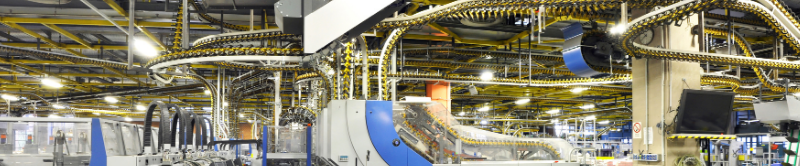

Ensure That The Manufacturing Floor Is Secured

Most persons tend to use contract manufacturers. However, if these manufacturers have an assembly plant, you’re required to utilize the fault-free environment. Even if OEM does not own the property, it is still entitled to inspect the facility to ensure that the requirements are met. In the case where this doesn’t happen, products can be recalled simply because the law wasn’t followed accurately.

Secure The Shipments

When products reach their destination damaged and spoilt, they will be recalled. Most of the time, products are recalled mainly because of the damages that they suffer after they leave the manufacturing plant. So if you’re transporting delicate and non-delicate products, it’s best to do so in the most cautious and safe manner to avoid recalls because of shipment damages.

Implementing A Crisis Response Team

While product failure can still occur even when everything was done to the best of each department’s ability, there should still be some after support. Hence, it’s important to ensure that there’s a plan to deal with problems. When there is a plan, manufacturers are guided accordingly to the most suitable solution. In these instances, products can be saved and not forced to be recalled.

Crisis response teams are essential and necessary to ensure that new products are monitored very closely. This usually applies from the production stage all the way beyond the manufacturing stage. It gives everyone peace of mind since problems are identified and solved in an effective manner.

Takeaway

As we conclude, we’ve just looked at the top 10 tips on how to avoid product recalls. Products can be recalled for having faulty components or when the manufacturers produce them without following strict environmental guidelines. So, if you’re interested in saving yourself from a product recall, it’s best to get everyone at the different development stages involved very early on!